Introduction:We specialize in producing glass brackets suitable for various scenarios. Our advertising screw series logo stands come in different specifications to meet different needs. I believe we can provide reliable and efficient solutions.

Standoff Screws for Signs is a hardware accessory specially used for installing and fixing signage. From the appearance, it usually consists of two main parts: a screw rod with a thread on one end and a decorative cylindrical cap on the other end. The whole is made of stainless steel, showing the unique luster and texture of metal. Its design purpose is to separate the signage from the installation surface by a certain distance, making the signage more prominent and three-dimensional, and also to play a role in stable installation, ensuring that the signage can remain stable and beautiful in various environments.

Our stainless steel standoffs are perfect for any modern and contemporary design that requires a sleek and functional support system. Made from high-quality stainless steel, these standoffs are built to last and are perfect for glass panels, signs, art pieces, and more. They are available in a range of sizes and finishes, including satin, mirror, allowing you to choose the perfect aesthetic for your project.

Our Stainless Steel Standoff are easy to install and can be used in a variety of applications, including residential and commercial projects. They provide a modern alternative to traditional mounting hardware and allow for a floating effect that adds depth and sophistication to any installation. Plus, they are durable and sturdy enough to support heavy glass pieces and can withstand harsh weather conditions.

So if you're looking for a reliable and stylish way to mount glass, look no further than our standoffs. With their sleek design and durable construction, they're sure to provide the perfect accent to any modern and contemporary project.

| Sku: | SS19-25S |

| Finish: | Satin Brushed |

| Inside/Outside: | Inside or Outside Use |

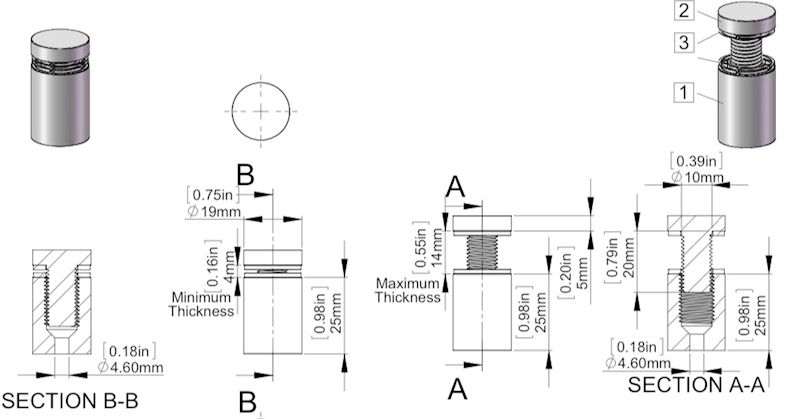

| Diameter: | 19mm |

| Distance From Wall: | 25mm |

| Cap height: | 5mm |

| Shape: | Cylinder |

| Process: | Stainless Steel Signage Standoff Screws |

| Material: | Stainless Steel |

| Solid/Hollow: | Solid |

| Length: | Different Length Available,You Can Also Customize The Size |

| Other Diameter: | 12mm / 16mm / 19mm / 25mm / 30mm / 38mm, Etc. |

| Customized: | Can Provide Customized Graphics |

| Material Grade: | 201or304 |

| Factory Nature: | China Manufacturers Suppliers Factory |

With our understanding of the uniqueness of hardware and stainless steel products, customization is one of the focuses of our services to meet the specific needs of customers.

Excellent material: Standoff Screws for Signs are made of stainless steel, mainly available in 201 and 304 grades. Stainless steel has excellent corrosion resistance, thanks to the chromium element in its chemical composition, which can form a dense oxide film on the surface, effectively preventing the erosion of foreign substances. Taking 304 stainless steel as an example, in a general humid environment, its corrosion resistance can ensure long-term use without rusting. Compared with ordinary carbon steel, its service life is greatly extended, reducing the frequency of screw replacement due to material corrosion.

Multiple diameter specifications: Provide a variety of diameter options, such as 12mm, 16mm, 19mm, 25mm, 30mm, 38mm, etc. Standoff screws of different diameters are suitable for signboards of different sizes and weights. For example, screws with smaller diameters (such as 12mm) are suitable for installing small, lightweight signboards, while screws with larger diameters (such as 38mm) can better support large, heavier signboards and ensure the stability of installation. This diverse selection of specifications meets the needs of different signboard installations.

Customizable length: There are different lengths to choose from, and custom sizes are supported. According to the thickness of the sign and the installation surface, users can choose the appropriate length of the spacing screw. For example, when the sign is thick, a longer screw is required to ensure that there is enough spacing between the sign and the installation surface; for thinner sign, a shorter screw can meet the requirements. Customization service further meets the personalized needs in special installation scenarios.

Solid structure: The solid structure design makes the spacing screw have higher strength and stability. The solid structure can withstand greater tension and pressure, and it is not easy to deform or damage after the sign is installed. Experiments show that solid stainless steel spacing screws can still maintain structural integrity when subjected to forces exceeding their rated loads, ensuring the safe installation of the sign.

Beautiful and decorative: The cap part of the spacing screw has a certain decorativeness, and its surface can be polished and other treatments to present a smooth and bright appearance. After the sign is installed, the cap part can play a decorative role and enhance the overall visual effect of the sign. Paired with the sign, it makes the entire sign system more beautiful and coordinated, and enhances the attractiveness and professionalism of the sign.

Customized graphic service: Customized graphic service can be provided. Users can customize specific graphics, logos or texts on the cap surface of the spacing screws according to their needs. This service makes the spacing screws not only a mounting accessory, but also a part of the sign, further strengthening the brand image or conveying specific information to meet the personalized needs of users.

Easy installation: The installation process is relatively simple. Usually, you only need to drill holes in the mounting surface, then pass the screw rod through the sign and the mounting hole, and finally fix it with nuts. Ordinary users can easily complete the installation without complex tools and professional skills. Compared with some other installation methods, it greatly saves installation time and labor costs.

Good compatibility: It can be compatible with various types of signboards and mounting surfaces. Whether it is a signboard made of wood, metal, plastic and other materials, or a mounting surface such as wall, glass, stone, etc., the stainless steel signboard spacing screw can adapt well and provide a stable installation effect. This wide compatibility allows it to be used in the installation of signboards in different scenarios.

Commercial Place Signs: In shopping malls, supermarkets, shops and other commercial places, Standoff Screws for Signs are widely used for the installation of various signboards. For example, shop signs, floor signs, and product display area signs in shopping malls. Using spacing screws to install can make the signboard more eye-catching, attract customers' attention, and enhance the image and brand recognition of commercial places. At the same time, due to the large flow of people in commercial places, signboards need to be frequently touched and collided. The high strength and stability of spacing screws can ensure that the signboards are always firmly installed and not easily damaged.

Office Area Signs: In office buildings and offices, signboard spacing screws are used to install office door signs, floor index signs, emergency exit signs, etc. Neat and beautiful signboard installation helps to improve the standardization and professionalism of the office environment, and facilitates employees and visitors to quickly find the required location. Moreover, signboards in office areas usually need to be used for a long time. The corrosion resistance and durability of spacing screws ensure the stable installation and good appearance of signboards over a long period of time.

Hotel Signage System: The hotel's signage system is very important, including hotel name signs, room number signs, service facility signs, etc. Signage spacing screws can provide a stable installation for these signs, making the overall image of the hotel more upscale and refined. The hotel environment is usually humid, especially in areas such as bathrooms and swimming pools. The corrosion resistance of stainless steel spacing screws enables it to adapt to this environment and ensure the normal use and beauty of the sign.

Public facility signs: In public facilities such as parks, libraries, museums, and hospitals, signage spacing screws are used to install various signs, instructions, etc. These signs play an important role in guiding the public and providing information. The installation method of spacing screws makes the signs clearer and easier to read, and its reliable performance ensures the long-term and stable use of signs in various public environments, providing convenience for the public.

Exhibition display signs: In exhibitions, museum exhibitions and other exhibition and display activities, signage spacing screws are used to install exhibit instructions, exhibition area signs, etc. Exhibition activities usually have high requirements for the installation effect and stability of signage. Spacing screws can keep the signage at a certain distance from the exhibits or display boards, enhance the three-dimensional sense and visual effect, and ensure that the signage will not loosen or fall during the exhibition, ensuring the smooth progress of the exhibition.

Traffic sign field: In the installation of some small traffic signs, such as signs in parking lots, traffic guide signs in residential areas, etc., sign spacing screws can also play a role. It can firmly install the sign on the wall, column and other locations, so that the sign can withstand the test of natural conditions such as wind, rain, sun and rain in outdoor environments, remain clear and stable, and provide accurate information for traffic participants.

Regular cleaning: Clean the sign spacing screws regularly to remove dust, dirt and other impurities on the surface. You can use a clean soft cloth to wipe it. For more stubborn stains, you can gently wipe it with a neutral detergent, then rinse it with clean water, and finally wipe it with a dry cloth. The cleaning frequency can be determined according to the use environment, generally once every two weeks. During the cleaning process, be careful to avoid using sharp objects to scratch the surface of the screws to avoid damaging its decorative coating.

Check for looseness: Check the spacing screws for looseness every once in a while. Due to environmental factors or external forces, the screws may gradually loosen and affect the stability of the sign. A comprehensive inspection can be carried out every three months, and the sign is gently shaken by hand to feel whether the screws are firm. If looseness is found, it should be tightened in time with appropriate tools to ensure that the sign is firmly installed.

Prevent chemical corrosion: Avoid contact between the spacing screws with chemicals such as strong acids and alkalis. Although stainless steel has a certain degree of corrosion resistance, long-term contact with highly corrosive substances may still cause damage to it. If chemical substances are accidentally splashed, they should be rinsed with clean water immediately and wiped dry with a soft cloth. When using detergent to clean the surrounding environment, be careful to choose products that are non-corrosive to stainless steel.

Avoid external impact: During daily use and maintenance, avoid external impact on the spacing screws. External impact may cause the screws to deform and damage, affecting their installation effect and aesthetics. For example, be careful not to touch the sign and spacing screws when moving items, and do not use excessive force to push and pull the sign when cleaning.

Surface maintenance: In order to maintain the gloss and beauty of the spacing screws, surface maintenance can be performed regularly. You can use a special stainless steel maintenance agent and apply it evenly on the surface of the screw with a soft cloth to form a protective film to prevent surface oxidation and dirt adhesion. The maintenance frequency can be determined according to the use environment, generally once every two months. When applying the maintenance agent, pay attention to even coverage to avoid omissions or accumulation.

Winter protection: In the cold winter, if the sign is installed outdoors, pay attention to protecting the spacing screws. Low temperatures may cause the metal to become brittle and increase the risk of screw damage. Before the arrival of winter, you can check the tightness of the screws and increase the inspection frequency appropriately. If you encounter severe weather such as heavy snow and freezing, you should promptly remove the snow and ice on the signboard and screws to avoid deformation or damage of the screws due to the weight of snow and ice.

Replace damaged screws: If the spacing screws are found to be damaged, such as broken, severely deformed, etc., they should be replaced in time. Using damaged screws will not only affect the installation stability of the signboard, but may also cause the signboard to fall off, causing safety hazards. When replacing screws, choose stainless steel screws with the same specifications as the original screws to ensure the installation effect and safety.

Record maintenance information: Establish maintenance records for the signboard spacing screws, and record the time and situation of each cleaning, inspection, repair and replacement. By recording maintenance information, you can timely understand the use status and maintenance history of the screws, provide a reference for subsequent maintenance work, and ensure that the signboard is always in a good installation state.

The key benefits of Standoff Screws for Signs include faster installation, consistent screw placement, reduced worker fatigue, and minimal wastage. They are also versatile, available in various lengths and thread types, making them ideal for different materials like wood or metal studs.

Standoff Screws for Signs are designed to be used with specific screw guns that can accommodate the collated strips or coils. It is important to check the compatibility of the screw gun before using collated screws to ensure smooth operation and prevent jamming during installation.

Standoff Screws for Signs can be used with both wood and metal studs, depending on the thread type. Coarse-thread screws are ideal for wood, while fine-thread screws are better suited for metal studs. This versatility makes them a popular choice for different construction projects.

No, Standoff Screws for Signs are not designed to be reusable. Once installed, they are meant to provide a permanent hold between the drywall and the studs. Removing the screws can damage both the drywall and the screw, rendering them unusable for future projects.

DILANGSI Hardware factory also has an experienced team and is equipped with advanced machinery and technology,Having rich experience in foreign trade exports, enabling us to efficiently and quickly produce high-quality products.With our understanding of the uniqueness of hardware and stainless steel products, customization is one of the focuses of our services to meet the specific needs of customers.

About Product Delivery | |

| Supply Ability | 10000 Pieces Per Week |

| Package | Cartons, wooden boxes, pallets, packaged according to weight and customer requirements |

| FOB Port | Shipping according to customer needs |

| MOQ | 100 pcs |

| Delivery Time | Samples in 7 days, cargo in 30 days, the time depends on the quantity the order |

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now