Introduction:We specialize in producing glass brackets suitable for various scenarios. Our advertising screw series logo stands come in different specifications to meet different needs. I believe we can provide reliable and efficient solutions.

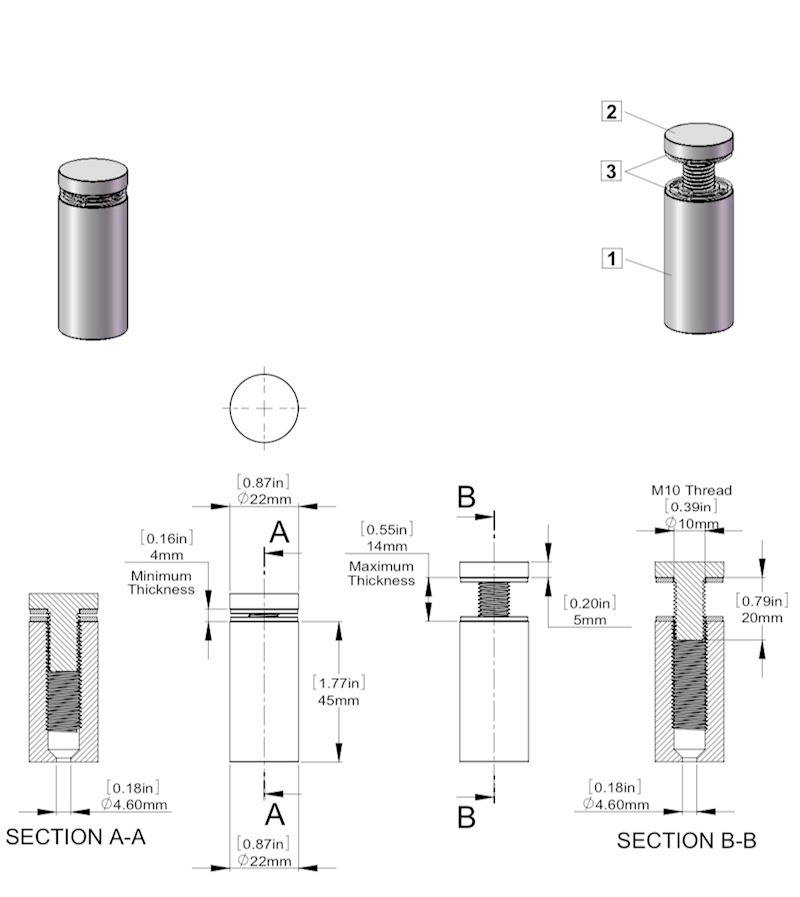

Sign Standoff Screws are a special screw assembly designed for fixing signage. It usually consists of two main parts, a stud with a decorative round head on one end and a threaded part for installation and fixing on the other end. This type of stud is made of stainless steel, with a cylindrical appearance, smooth surface and metallic luster. Its core function is to separate the signage from the mounting surface at a certain distance, creating a three-dimensional, suspended visual effect, while enhancing the stability and durability of the signage.

Our stainless steel standoffs are perfect for any modern and contemporary design that requires a sleek and functional support system. Made from high-quality stainless steel, these standoffs are built to last and are perfect for glass panels, signs, art pieces, and more. They are available in a range of sizes and finishes, including satin, mirror, allowing you to choose the perfect aesthetic for your project.

Our Stainless Steel Standoff are easy to install and can be used in a variety of applications, including residential and commercial projects. They provide a modern alternative to traditional mounting hardware and allow for a floating effect that adds depth and sophistication to any installation. Plus, they are durable and sturdy enough to support heavy glass pieces and can withstand harsh weather conditions.

So if you're looking for a reliable and stylish way to mount glass, look no further than our standoffs. With their sleek design and durable construction, they're sure to provide the perfect accent to any modern and contemporary project.

| Sku: | SS22-45S |

| Finish: | Satin Brushed |

| Inside/Outside: | Inside or Outside Use |

| Diameter: | 22mm |

| Distance From Wall: | 45mm |

| Cap height: | 5mm |

| Shape: | Cylinder |

| Process: | Stainless Steel Signage Standoff Screws |

| Material: | Stainless Steel |

| Solid/Hollow: | Solid |

| Length: | Different Length Available,You Can Also Customize The Size |

| Other Diameter: | 12mm / 16mm / 19mm / 25mm / 30mm / 38mm, Etc. |

| Customized: | Can Provide Customized Graphics |

| Material Grade | 201or304 |

| Factory Nature: | China Manufacturers Suppliers Factory |

With our understanding of the uniqueness of hardware and stainless steel products, customization is one of the focuses of our services to meet the specific needs of customers.

stainless steel material, excellent corrosion resistance: The Sign Fixing Screws are made of stainless steel, and the material grades are mainly 201 and 304. In terms of corrosion resistance testing, it has strict standards and excellent performance. Taking the salt spray test as an example, 304 stainless steel was subjected to continuous spray test in a 5% neutral salt spray environment, and slight rust only appeared after 720 hours; while 201 stainless steel showed slight signs of rust in about 480 hours under the same test conditions. This excellent corrosion resistance enables the sign isolation studs to effectively resist oxidation and corrosion in harsh environments such as humidity and dust, ensuring long-term use without rust or damage, greatly extending their service life. Its core function is to provide long-lasting and stable support for the sign, ensuring that the sign can be used normally in various environments.

Solid structure, high strength and stability: The solid structure design gives the sign isolation studs high strength and excellent stability. After professional mechanical performance testing, the solid sign isolation studs perform well when subjected to vertical loads. Taking a stud with a diameter of 19mm and a length of 50mm as an example, it can withstand a vertical static load of up to 500kg without obvious deformation or breakage. This feature enables it to easily withstand the weight of the sign and a certain impact force that may be applied by the outside world, providing reliable support for the sign, ensuring that the sign can be firmly installed in the designated position and will not easily shake or fall due to external forces.

A variety of lengths are available to meet diverse installation needs: In order to adapt to the requirements of signboards of different thicknesses and various installation spacings, the sign isolation stud provides a rich variety of length specifications and supports customized services. Its length range can cover different sizes such as 25mm - 200mm. For example, for a signboard with a thickness of 10mm, a stud with a length of 30mm can be selected, so that after installation, there will be a suitable distance between the signboard and the installation surface, which not only ensures the aesthetics, but also facilitates people to watch; and for some special installation spaces, the customized length can be accurately adapted to meet various complex design requirements. Its core function is to achieve the ideal isolation and fixation of the signboard and the installation surface, so that the signboard can present the best display effect.

Multiple diameters, flexible to fit different signboards: Sign isolation studs have multiple diameters, such as 12mm, 16mm, 19mm, 25mm, 30mm, 38mm, etc. Studs of different diameters are suitable for signboards of different sizes. For example, for small signboards, studs with a diameter of 12mm can provide delicate and compact support, which will not make the signboard appear too abrupt; while for large outdoor signboards, studs with a diameter of 38mm can provide more stable and reliable support, ensuring that the signboard can remain stable in all kinds of bad weather conditions. This variety of diameter specifications can meet different design requirements, and its core function is to adapt to the installation of signboards of different sizes, so that the signboard is more coordinated with the installation environment.

Multiple diameter specifications, flexible matching to meet diverse needs: As mentioned earlier, there are multiple diameter specifications, such as 12mm, 16mm, 19mm, 25mm, 30mm, 38mm, etc. Studs of different diameters are suitable for signboards of different sizes. Taking a small sign as an example, a 12mm diameter stud can provide delicate and compact support for it, making the sign look more delicate and beautiful; while for a large outdoor sign, a 38mm diameter stud can provide more stable and powerful support, ensuring that the sign can remain stable even in severe weather conditions such as strong winds. This variety of diameter specifications can meet different design requirements. The core function is to adapt to the installation of signs of different sizes, so that the sign can be properly fixed in various scenarios.

Customizable graphics to enhance the recognition of signs: The ability to provide customized graphic services is a major feature of the sign isolation stud. Unique patterns, logos or texts can be made on the surface of the sign isolation stud according to the special needs of customers. Through high-precision laser engraving technology, the pattern accuracy can reach 0.1mm, which can clearly and accurately present complex graphics and text. This feature greatly enhances the uniqueness and recognition of the sign, allowing it to better integrate into the overall design style and meet the personalized brand promotion and design needs of customers.

Precise thread design ensures stable installation: The thread part adopts a precise design, with a tooth angle of 60° and a pitch accuracy of ±0.1mm. This precise thread design ensures that during the installation process, the identification isolation stud is tightly and firmly connected to the mounting base and the identification plate, and is not prone to loosening. Even in long-term use and under external force vibration, it can maintain a stable installation state. Its core function is to ensure the stability of the installation of the identification plate, prevent the identification plate from falling due to looseness, causing safety hazards or affecting the identification effect.

Commercial Place Signage: In shopping malls, supermarkets, shops and other commercial places, Sign Fixing Screws are widely used for the installation of various signage. For example, the shop signs in the mall will be more prominent and eye-catching after being installed with sign isolation studs, which can quickly attract customers' attention and enhance the overall image and brand recognition of the commercial place. At the same time, its stable installation method can ensure that the signage will not fall or be damaged easily in an environment with frequent personnel flow, providing customers with clear and accurate guidance.

Office Area Signage: In office areas such as office buildings and offices, sign isolation studs are used to install office door numbers, floor index signs, conference room signs, etc. It can not only create a neat and professional atmosphere for the office area, but also make it convenient for people to quickly find the required office location. Moreover, customized sign isolation studs can match the decoration style of the office environment, further enhancing the overall aesthetics and coordination.

Hotel Signage System: The signage system in the hotel is complex and diverse, including room door numbers, lobby signs, restaurant signs, etc. The use of sign isolation studs can make the hotel signage more refined and high-end, complementing the hotel's luxurious decoration style. Moreover, its good corrosion resistance and stability can ensure that the signboard remains in good condition during long-term use, providing guests with clear and accurate guidance and enhancing the guest's stay experience.

Exhibition display signs: In various exhibitions and fairs, sign isolation studs are used to fix exhibit signs, booth signs, etc. It can separate the signboard from the exhibits or booths at a certain distance, making the sign more prominent and convenient for visitors to watch. At the same time, according to different exhibition themes and styles, sign isolation studs of different specifications and styles can be selected to better integrate into the exhibition environment and enhance the visual effect and information communication effect of the exhibition.

Public facility signs: In public facilities such as parks, libraries, museums, and hospitals, sign isolation studs are used to install various signs, instruction signs, etc. For example, scenic spot signs in parks, classification signs in libraries, and department signs in hospitals. Its stable performance and diverse specifications can meet the installation needs of different public facilities, provide people with clear and convenient information guidance, and improve the service quality of public facilities.

Educational institution identification: In educational institutions such as schools and training institutions, identification isolation studs are used to install classroom doorplates, campus signs, library signs, etc. It can help teachers, students and visitors quickly find the classrooms and facilities they need, and at the same time enhance the cultural atmosphere and overall image of the campus. Customized identification isolation studs can also incorporate the school's characteristic elements, such as the school emblem and school motto, to enhance the school's brand recognition.

Industrial site identification: In industrial sites such as factories and workshops, identification isolation studs are used to install equipment identification, safety warning signs, etc. Due to the harsh environment of industrial sites, there may be factors such as oil, dust, and moisture. Stainless steel identification isolation studs can adapt well to these environments, ensure that the sign is clearly visible and stably installed, and provide necessary information support and safety guarantees for industrial production.

Transportation hub identification: In transportation hubs such as airports, railway stations, and bus stations, identification isolation studs are used to install flight information signs, station signs, safety warning signs, etc. In densely populated and highly mobile transportation hubs, the stability and durability of sign isolation studs are crucial to ensure that signboards remain intact under long-term use and various external forces, providing accurate and timely information services to passengers.

Commercial building facade signs: Large signboards are often installed on the facades of commercial buildings to display brand information. Sign isolation studs can separate these signboards from the building walls at a certain distance, creating a three-dimensional sense, so that the signboards can be clearly seen from a distance. Moreover, the stainless steel material can withstand the erosion of the natural environment such as wind, sun, and rain, ensuring the long-term and stable display of the signboard.

Clean the surface regularly: In order to maintain the beauty and performance of the sign isolation studs, they need to be cleaned regularly. You can use a clean soft cloth to gently wipe the surface of the sign isolation studs to remove dust, stains, etc. attached to it. If there is oil or stubborn stains on the surface, you can dip a soft cloth in a small amount of mild neutral detergent and gently wipe the dirt. Neutral detergent can effectively remove dirt without damaging the stainless steel surface. After wiping, rinse with clean water and wipe dry with a dry cloth to avoid water stains. Avoid using detergents containing abrasive particles, strong acids, alkalis or solvents, as these detergents may scratch or corrode the stainless steel surface, affecting its beauty and service life.

Check the installation firmness: The installation firmness of the sign isolation studs needs to be checked every once in a while. Since the sign may be subjected to external forces, such as wind blowing, collision, etc., the studs may become loose. When checking, you can gently shake the sign with your hand to observe whether the studs show signs of shaking. If looseness is found, appropriate tools should be used to tighten it in time to ensure the stable installation of the sign and prevent the sign from falling and causing safety accidents.

Avoid collision with hard objects: During daily use and maintenance, special attention should be paid to avoid collision with hard objects on the sign isolation studs. The surface coating and internal structure of the sign isolation studs are relatively precise. Collision with hard objects may cause scratches, deformation, and even damage to internal components. If a collision occurs accidentally, stop using it immediately and carefully check whether its function is normal, such as whether the thread is damaged and whether the sign is installed firmly. If any abnormality is found, contact a professional for inspection and repair in time to prevent the problem from further expansion.

Prevent chemical corrosion: Avoid contact between the sign isolation studs and strong acids, strong alkalis and other chemicals. These chemicals may corrode stainless steel and reduce the strength and corrosion resistance of the studs. For example, in some chemical companies or laboratory environments, special attention should be paid to prevent chemicals from splashing on the sign isolation studs. If you accidentally come into contact with chemicals, rinse them immediately with clean water and wipe them dry with a dry cloth. If it has been exposed to chemicals, it should be immediately rinsed with plenty of clean water and wiped with a dry cloth. If necessary, it can be cleaned with a neutral detergent and then wiped with a dry cloth.

Regularly check the threaded part: Regularly check whether the threaded part of the identification isolation stud is damaged or rusted. The integrity of the threaded part is crucial to the firmness of the installation. If the thread is found to be damaged or rusted, it can be treated with a rust remover. If the damage is serious, a new stud should be replaced. At the same time, during the installation process, ensure that the thread connection is tight to avoid loosening or stripping.

Pay attention to environmental influences: Under different environmental conditions, the maintenance focus of the identification isolation stud is also different. For example, in a humid environment, pay attention to prevent moisture from accumulating on the surface of the stud, wipe it dry in time, and avoid moisture from corroding the stud; in a high temperature environment, avoid exposing the stud to high temperature for a long time to avoid affecting its material properties, because high temperature may cause changes in the grain structure of stainless steel and reduce its strength.

Regularly check the threaded part: Regularly check whether the threaded part of the identification isolation stud is damaged or rusted. The integrity of the threaded part is crucial to the firmness of the installation. If the thread is found to be damaged or rusted, a rust remover can be used to treat it. If the damage is serious, a new stud should be replaced. During the inspection, a magnifying glass can be used to carefully observe whether the thread profile is complete, whether there is wear or deformation, etc.

Pay attention to environmental impact: Under different environmental conditions, the maintenance focus of the identification isolation stud is also different. For example, in a humid environment, be careful to prevent moisture from accumulating on the surface of the stud and wipe it dry in time, because moisture may cause water stains on the stainless steel surface, affecting the appearance, and long-term water accumulation may also accelerate the corrosion process; in a high temperature environment, avoid exposing the stud to high temperature for a long time to avoid affecting its material properties, because high temperature may change the crystal structure of stainless steel and reduce its strength and toughness.

Lubricate the thread regularly: For the threaded part, a small amount of lubricant, such as grease, can be applied regularly to ensure smooth rotation of the thread. When applying lubricant, pay attention to the moderate amount to avoid excessive dripping of lubricant onto the sign or installation surface. Lubricant can reduce friction between threads and extend the service life of studs. It is generally recommended to perform lubrication maintenance every 3-6 months.

Replace damaged studs in time: If the sign isolation studs are found to be seriously damaged, such as broken or deformed, they should be replaced with new ones in time. Using damaged studs may cause unstable installation of the sign and pose a safety hazard. When replacing studs, choose products with the same specifications and materials as the original studs to ensure compatibility and stability of the installation. When replacing studs, pay attention to the order and method of installation to ensure that the new studs can firmly fix the sign.

Our Stainless Steel Standoff Screws are made from premium stainless steel, ensuring exceptional strength, rust resistance and magnificent polish.

These screws are suitable to hold signage boards, glass panels, display boards or any other architectural structure that requires a professional appearance.

They have been created for simple installation and do not need complex tools. They come with all necessary hardware to ensure a secure and professional setup.

Certainly! These standoff screws are corrosion resistant due to being produced using high-quality stainless steel that does not rust making them perfectly suitable for both indoor and outdoor usage.

Yes, we provide a variety of custom-made items as one of major manufacturers in China Standoff Screws industry which will be able to fit your application precisely.

DILANGSI Hardware factory also has an experienced team and is equipped with advanced machinery and technology,Having rich experience in foreign trade exports, enabling us to efficiently and quickly produce high-quality products.With our understanding of the uniqueness of hardware and stainless steel products, customization is one of the focuses of our services to meet the specific needs of customers.

About Product Delivery | |

| Supply Ability | 10000 Pieces Per Week |

| Package | Cartons, wooden boxes, pallets, packaged according to weight and customer requirements |

| FOB Port | Shipping according to customer needs |

| MOQ | 100 pcs |

| Delivery Time | Samples in 7 days, cargo in 30 days, the time depends on the quantity the order |

WhatsApp:

WhatsApp: Mobile Phone:

Mobile Phone: Contact Now

Contact Now